Design of – Assembly Tooling, Machining fixtures, Jigs, inspection fixtures, CE marking.

1. 2D Drawings

2. 3D Models

3. Risk Assessment documentation

4. PUWER assessment

5. Standards documentation

6. Stress Analysis

7. Operating instructions

8. MFMEA

9. FMEA

10. Reverse engineering

11. NC programming

12. Component design and test

13. Manufacturing process development.

Case Studies

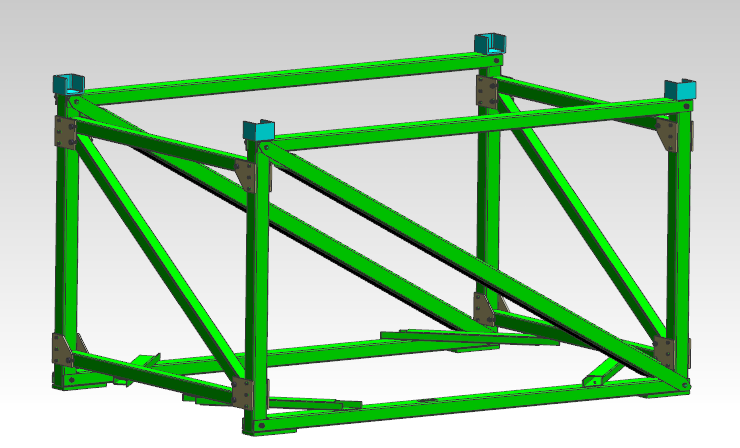

Engine Core Stand

We were asked to urgently design a work stand that could support the entire core of a Trent 1000 the weight of this is 8000Kg. The tool was required to be designed in such a way it could be flat packed to enable cheap and quick airfreight to the end user, the tool then must be assembled by 2 fitters on site. Precision Tool Design designed the tool in Siemens NX9 to the customer specifications within 3 weeks as required by the customer. Supplied with the design was a full technical package including the following

- 3D models

- 2D drawings

- Operating instructions

- Risk assessments

- Stress Report

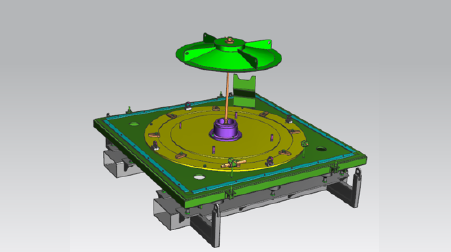

Fan Assembly Installation and Removal Tool

We were asked to design an assembly fixture that enables the assembly and dis-assembly of the fan blades and fan shaft assembly to the Trent 1000. This tool was an urgent requirement, so we worked in conjunction with the customer and the manufacturing company to concurrently design and manufacture this tool. The tool was complete through design and manufacture in 3 weeks. Precision Tool Design Designed the Tool in Siemens NX9 to the customer specifications. Supplied with the design was a full technical package including the following

- 3D models

- 2D drawings

- Operating instructions

- Risk assessments

- Stress Report

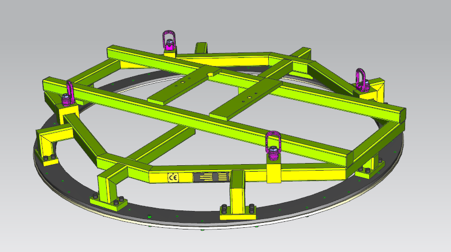

Module Lifter

We were asked to design a lifting tool that could lift the entire 05 module of a Trent XWB between assembly and machining operations. Precision Tool Design Designed the Tool in Siemens NX9 to the customer specifications. Supplied with the design was a full technical package including the following

- 3D models

- 2D drawings

- Operating instructions

- Risk assessments

- Declaration of conformity

- Stress Report

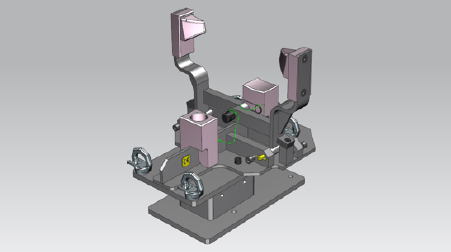

Module Machining Fixture

We were asked to design a machining fixture that accommodates entire 05 module of a Trent XWB and allows various machining operations. Precision Tool Design Designed the Tool in Siemens NX9 to the customer specifications. Supplied with the design was a full technical package including the following

- 3D models

- 2D drawings

- Operating instructions

- Risk assessments

- Stress Report

Air Turbine Lifting Fixture

We were asked to design a lifting tool that accommodates the air turbine starter of a Trent 7000 jet engine. Precision Tool Design Designed the Tool in Siemens NX9 to the customer specifications. Supplied with the design was a full technical package including the following

- 3D models

- 2D drawings

- Operating instructions

- Risk assessments

- Stress Report

- Declaration of conformity

Module Transportation Stand

We were asked to design a transportation stand that fit the entire 03 module of a Trent XWB this transportation was to take place between facilities. Precision Tool Design Designed the Tool in Siemens NX9 to the customer specifications. Supplied with the design was a full technical package including the following

- 3D models

- 2D drawings

- Operating instructions

- Risk assessments

- Declaration of conformity

- Stress Report